Printsteals Fundamentals Explained

Printsteals Fundamentals Explained

Blog Article

More About Printsteals

Table of ContentsSome Of PrintstealsThe Main Principles Of Printsteals The Only Guide to Printsteals

Display printing, in nonprofessional's terms, is a printing strategy that entails utilizing a mesh screen to transfer ink onto a surface area, such as fabric, paper, or plastic - https://dzone.com/users/5181692/printsteals.html. A stencil called a screen, is created by blocking out areas where the ink need to not travel through. The ink is after that pressed via the open locations of the display onto the product under, developing a published layout: Apparel industry for publishing layouts on tees, hoodies, and various other garments; Marketing items market for creating products such as tote, caps, and personalized accessories; Creating vibrant and durable outdoor and interior indications; Manufacturing of posters, stickers, decals, and various other visuals prints. Not appropriate for complex or extremely comprehensive designs, as it can be testing to accomplish fine details with this approach; Can be taxing and labour-intensive, particularly when multiple colours are involved; Rise manufacturing costs for complex tasks.

It includes a versatile relief plate with elevated picture areas that transfers ink onto numerous substrates, such as paper, plastic, or film. business card printing san diego. Home plate rotates on a cyndrical tube, and as the substratum goes through the press, the tattooed plate rolls against it, developing the preferred print. Flexographic printing offers excellent print top quality, rapid production rates, and the capability to print on a wide variety of materials

Getting The Printsteals To Work

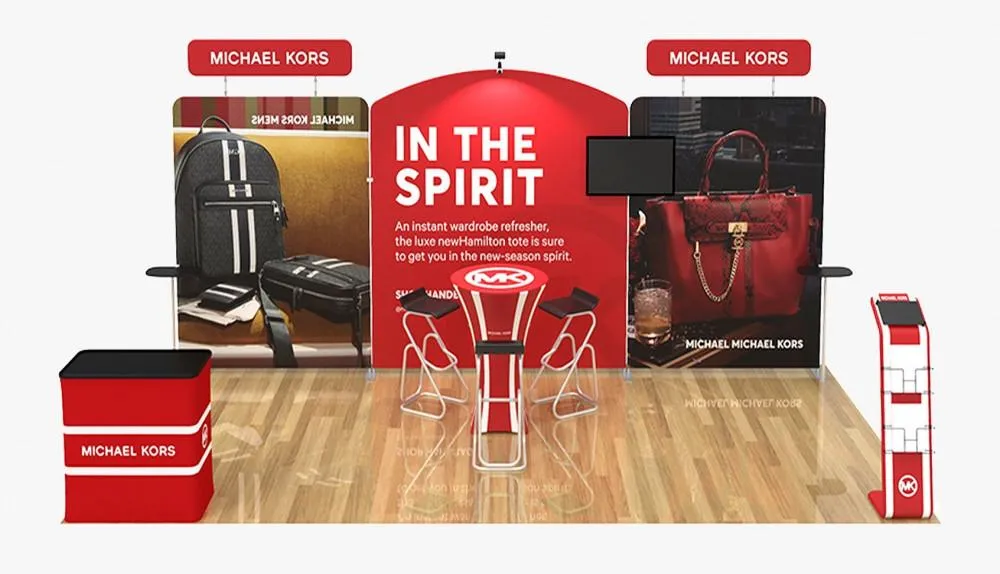

Large-format printing makes use of wide-format printers that can accommodate products with higher width, enabling the production of prints in dimensions that can range from numerous feet to several meters in size. This printing approach provides high-quality, attention-grabbing prints with vibrant colours and crisp details. It is an effective marketing device for organizations, event coordinators, and marketers seeking to make a strong aesthetic effect.

Fairly expensive compared to smaller-scale printing methods Logistics and installation of large-format prints can be difficult Needing specific devices and expertise to handle and place the extra-large prints effectively. Examine our overview on just how to begin a Big Style Printing Company. 3D printing, likewise referred to as additive manufacturing, is an innovative technology that enables the creation of three-dimensional objects from digital versions.

A 3D printer analyzes an electronic design documents and constructs the physical item by including product layer by layer up until the last product is full. https://packersmovers.activeboard.com/t67151553/how-to-connect-canon-mg3620-printer-to-computer/?ts=1722242185&direction=prev&page=last#lastPostAnchor. This technology permits the manufacturing of facility and elaborate shapes that may be hard or difficult to achieve with conventional production methods.: Item style and development for quick prototyping made use of by designers and designers; Employed for developing tailored medical implants, prosthetics, and surgical designs in the health care sector; Manufacture light-weight and complex parts for aircraft, lowering weight and enhancing fuel efficiency in the aerospace industry; Rapid prototyping, tooling, and even printing functional parts for vehicles in the vehicle market; Use in fashion jewelry production, style, education and learning, and creative productions

The smart Trick of Printsteals That Nobody is Talking About

LED UV refers to a type of UV (ultraviolet) treating innovation made use of in printing and coatings. Unlike conventional UV curing systems that make use of mercury-based lights, LED UV uses light-emitting diodes (LEDs) as the light. LED UV offers several benefits, consisting of power performance, longer life-span, and instantaneous on/off capacities. It gives off a narrow band of UV light that is concentrated on the healing process, leading to faster and extra effective drying or curing of inks, finishes, or adhesives on different substratums.

Each type has its own particular niche and market. By looking into and evaluating the target market, evaluating devices and expense factors to consider, and taking into consideration the specific printing demands of potential clients, aiming business owners can make enlightened decisions to begin an effective printing company. By using the ideal printing solutions, high quality items, and extraordinary client service, a printing organization can prosper in today's competitive market, dealing with the varied needs of customers and making a lasting influence in the market.

Report this page